Infrared Imaging Inspection – NFPA 70B Compliant

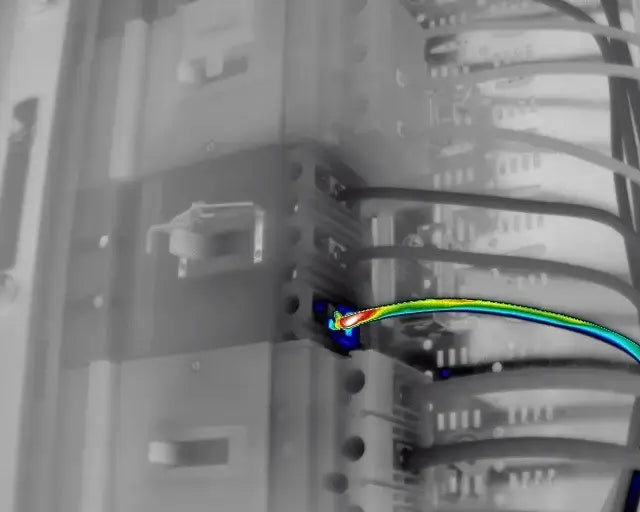

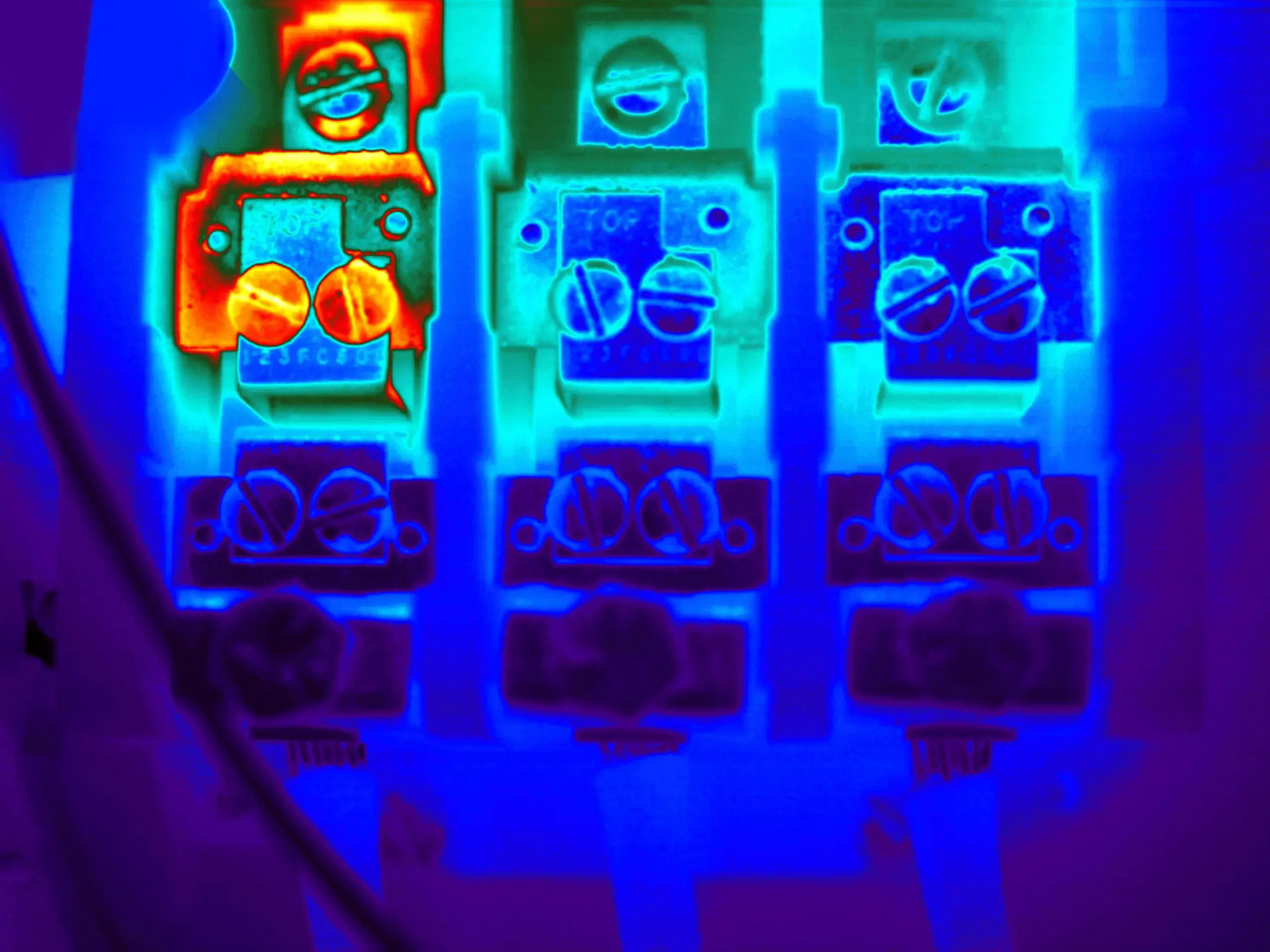

Advanced Thermal Imaging Technology

Ensure Compliance with NFPA 70B Standards

Proactive Maintenance to Prevent Failures

Comprehensive Reporting for Informed Decision-Making

Frequently Asked Questions

FAQs

What is NFPA 70B, and why is compliance important?

How often are infrared inspections required under NFPA 70B?

What constitutes "Condition 3" equipment?

What are the benefits of regular infrared inspections?

What types of issues can infrared imaging detect in electrical systems?

How can I schedule an inspection?